Is a PET packaging bottle recyclable? Is it also circular?

The European PET Bottle Platform (EPBP) provides test procedures for PET bottle innovations, ensuring they meet stringent recyclability and circularity standards. Before a new PET bottle design, material, or additive can be widely adopted, it must undergo rigorous testing and evaluation. This comprehensive assessment focuses on the impact on rPET properties and established recycling processes resulting from PET bottle innovations, such as:

- Barrier Materials

- Resin Formulations

- Non-PET Components

The EPBP assessment determines whether a PET bottle is suitable for:

- Single-Loop Recycling (Recyclable Material): This represents the minimum standard for recyclability. The PET material can be recycled once and used in a new product, but its properties may be degraded, limiting its potential for further recycling.

- Multiple-Loop Recycling (Circular Material): This is the ideal scenario, where the PET material can be recycled multiple times without significant degradation of its properties. This contributes to a closed-loop system, reducing reliance on virgin PET resin.

The presence of non-PET components can affect recycled PET by:

- Colour

- Clarity

- Mechanical Properties

- Processing

Quick Tests

The EPBP's Quick Tests provide rapid insights into the recyclability of PET bottles, allowing manufacturers to make informed decisions early in the development process. These tests can be executed in-house and provide results that are purely indicative. The results of the quick tests are purely indicative and are often used for the optimisation of further tests.

Download the EPBP Quick Tests here.

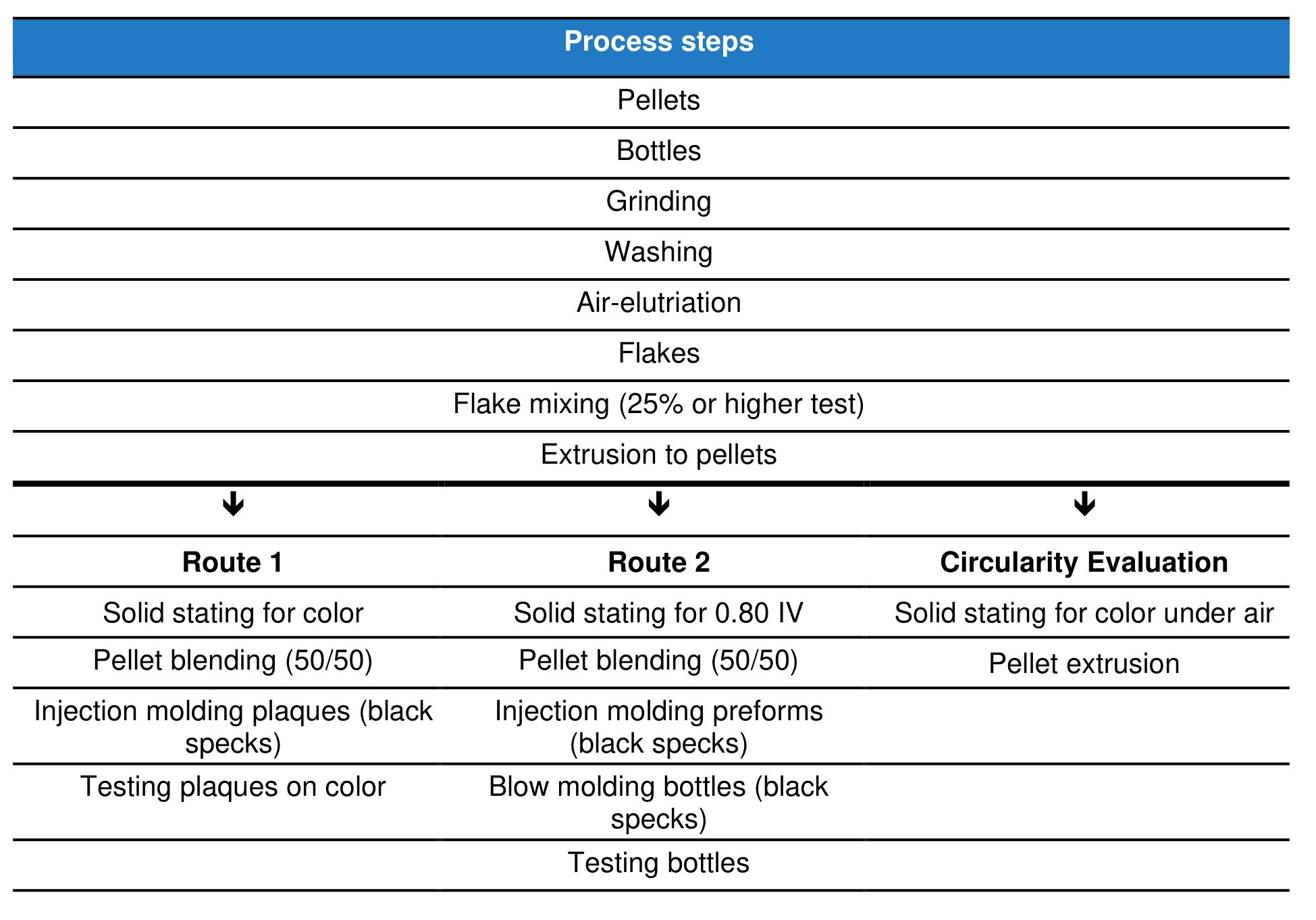

Testing Protocol for PET Recycling Compatibility

The EPBP has developed a comprehensive testing protocol to evaluate the compatibility of innovative PET bottles with established recycling systems. This protocol is designed to:

- Evaluate PET Bottle Solutions: Assess how innovative PET bottle solutions behave within the PET recycling stream.

- Identify Potential Impacts: Determine whether these solutions may influence the quality of the recycled material or potentially disrupt the recycling streams

The EPBP test protocol can also be used to evaluate the impact of other products (such as other PET packaging or non-PET packaging).

The ultimate objective within the PET value chain has traditionally been recyclability. This means ensuring that materials introduced into the market are effectively:

- Collected

- Sorted

- Reprocessed

- Returned to the market as recyclate

The PET Circularity Evaluation Protocol: Moving Towards Multiple-Loop Recycling

In response to evolving EU legislative mandates, the EPBP has developed the PET Circularity Evaluation Protocol. This protocol represents a shift towards a more circular approach, acknowledging that PET will undergo multiple recycling loops.

- Simulating Multiple Recycling Loops: The protocol is designed to simulate the effects of multiple recycling cycles on PET materials.

- Addressing Evolving Needs: It addresses the evolving needs of the PET industry as the demand for recycled PET (rPET) increases.

- Aligning with EU Policies and Legislation: The protocol is aligned with EU policies and associated legislation aimed at promoting circular economy principles.

The EPBP's team of experts leverages both information provided by applicants and their extensive knowledge database to:

- Determine the Optimal Test Program: Tailor testing programs to the specific characteristics of each PET bottle innovation.

- Employ Up-to-Date Testing Methods: Utilize state-of-the-art testing methodologies to generate qualitative and quantitative results.

- Assess Potential Problems: Identify potential issues that may arise during bottle-to-bottle single and/or multiple-loop recycling processes.

Products that successfully pass the EPBP's testing protocols are expected to perform well during recycling, without causing significant problems or disruptions.

Engaging with the EPBP: A Collaborative Approachrative

Engaging with the EPBP: A Collaborative Approachrative

The European PET Bottle Platform actively encourages companies involved in the development of new resins, additives, technologies, and processes for PET bottles to engage with the platform early in their innovation cycle. This proactive approach provides several benefits:

- Objective Third-Party Assessment: Receive an unbiased evaluation of the potential impact of your innovation on recyclability and circularity.

- Efficient and Economical Evaluation: Streamline the testing process, minimizing costs and maximizing resource utilization.

- Proactive Identification of Challenges: Identify and address potential recyclability issues early in the development process, reducing the risk of costly redesigns later on.

- Enhanced Market Acceptance: Demonstrate your commitment to sustainability and recyclability, enhancing the marketability of your product.

The EPBP Evaluation Process: A Step-by-Step Approach

The EPBP evaluation process is designed to be transparent, collaborative, and efficient. The process typically involves the following steps:

- Approach EPBP: Initiate contact with the EPBP to discuss your innovation and determine the appropriate evaluation path.

- Fill in Application Form: Complete the EPBP application form, providing detailed information about your innovation, its intended use, and its potential impact on recycling processes.

- Assess the Concentration in the Recycle Stream: Analyze the potential concentration of your innovation in the PET recycling stream to determine the scope of the evaluation.

- Test Critical Properties: Conduct specific tests to evaluate the critical properties of your innovation that are relevant to recyclability and circularity.

- Finalize Test Programme: Based on the information gathered in the previous steps, finalize the test program with the EPBP, specifying the testing methodologies and criteria to be used.

- Discussion: Engage in ongoing discussions with the EPBP throughout the evaluation process to address any questions or concerns that may arise.

- Decision: The EPBP will render a decision on the recyclability and circularity of your innovation based on the results of the testing and evaluation process.

The EPBP recognizes that the evaluation process may involve several discussions and iterations. However, the platform is committed to working collaboratively with applicants to minimize testing costs and streamline the evaluation path.

Taking the Next Step: Apply for an EPBP Evaluation

If you are interested in obtaining an evaluation of your PET bottle innovation by the European PET Bottle Platform, we encourage you to:

- Download the EPBP Test Protocol: Familiarize yourself with the EPBP testing methodologies and evaluation criteria.

- Download the Quick Test Documents: Explore the quick test options for preliminary assessment.

- Download the Application Documents: Prepare the necessary documentation for submitting your application.

The documents can be found here

Contact the EPBP: Reach out to the EPBP directly to discuss your innovation and initiate the evaluation contact us.

Accredited laboratories

The EPBP requires that specific tests be conducted by independent testing laboratories that have been approved by the platform. These laboratories:

- Provide Expertise: Offer specialized knowledge and experience in testing PET materials.

- Utilize Modern Equipment: Employ state-of-the-art testing equipment that meets EPBP standards.

- Adhere to EPBP Protocols: Conduct testing in accordance with established EPBP protocols and evaluation requirements.

A list of testing laboratories accredited by the EPBP can be found , click here.

Validation of test results

A panel of technical experts specializing in PET production, design, and recycling evaluates all test results to assess the impact of new packaging technologies on PET recycling processes across Europe. The EPBP expert panel conducts these assessments while safeguarding the confidentiality of applicants’ proprietary and confidential information. Innovations that meet the test criteria are considered recycling-compatible, provided the defined conditions are respected.

To find out which PET bottle technologies have been positively assessed by the European PET Bottle Platform, click here.

Downloads

-

Modus Operandi , NDA , Application for Technical Assessment

The Assessment Process document explains the general rules, the different steps and tools used during the test procedure. Fill in the application form if you wish to apply for an evaluation of a new PET bottle innovation by our EPBP experts.

-

Modus Operandi

Modus Operandi

The main objective of the European PET Bottle Platform is to evaluate technologies / products and to allow new PET bottle innovations, while optimizing the economic and environmental consequences for the European PET recycling industry. It will do so by promoting the recyclability of PET bottles on the market by: • Establishing European harmonized guidelines for PET bottles recyclability and that will be accepted across the whole value chain. • Encouraging industry to test new PET bottle concepts and/or materials before market launch according to the harmonized guidelines. • Giving advice and recommendations to the different stakeholders. • Sharing information and knowledge across the whole value chain.

-

EPBP panel of experts - update January 2025

EPBP panel of experts - update January 2025

-

NDA for Applicant

NDA for Applicant

-

Accredited Laboratories

Accredited Laboratories

-

Application form

Application form

-

-

Evaluation Protocols

EPBP's Comprehensive Testing Protocols: Ensuring Quality and Circularity in PET Recycling

From its inception, the European PET Bottle Platform (EPBP) has been committed to developing and refining robust testing protocols to assess the recyclability and circularity of innovative PET packaging solutions. These protocols are specifically designed to evaluate how new PET bottle designs, materials, and additives behave within the established PET recycling stream. The core objective is to identify any potential impacts – positive or negative – that these innovations may have on the quality, efficiency, and integrity of the recycling system.

The protocols can also be used to evaluate the impact of other products (such as other PET packaging or non-PET packaging).

The primary goal of these protocols is to ensure that PET packaging solutions introduced to the market:

- Are Compatible with Existing Recycling Infrastructure: The protocols assess whether new PET materials can be effectively collected, sorted, and processed using existing technologies.

- Do Not Compromise the Quality of Recycled PET (rPET): The protocols evaluate the potential for new materials to contaminate or degrade rPET, impacting its color, clarity, mechanical properties, and processability.

- Support the Transition to a Circular Economy: The protocols promote the design and adoption of PET packaging solutions that can be recycled multiple times without significant degradation, minimizing reliance on virgin resources.

The Shift Towards Circularity: Adapting to EU Legislative Mandates

In response to evolving EU legislative mandates and a growing emphasis on circular economy principles, the EPBP has expanded its testing protocols to address the challenges and opportunities associated with multiple-loop recycling. These mandates include:

- Increased targets for the use of recycled content in packaging.

- Extended Producer Responsibility (EPR) schemes that incentivize the design of recyclable and circular packaging.

- Harmonized standards for the collection, sorting, and recycling of packaging waste.

Key EPBP Testing Protocols: A Detailed Overview

- EPBP Circularity Evaluation Protocol: This protocol goes beyond basic recyclability and assesses the potential for PET packaging solutions to be recycled multiple times without significant degradation. It evaluates the long-term performance of materials in a closed-loop system, taking into account factors such as:

- Changes in material properties over multiple recycling cycles.

- The impact of processing conditions on rPET quality.

- The potential for cross-contamination with other materials

- EPBP Recyclability Evaluation Protocol: This protocol focuses on assessing the basic recyclability of PET packaging solutions. It evaluates whether a new material can be effectively collected, sorted, and reprocessed into rPET using established recycling technologies.

Accessing the Full Test Protocols and Accredited Laboratories

The full versions of the EPBP testing protocols are available to accredited laboratories.

- To find out which testing laboratories have been been accredited by EPBP, click here.

-

EPBP Circularity Evaluation Protocol - website version

EPBP Circularity Evaluation Protocol - website version

Update July 2025: The circularity evaluation protocol reflects the evolving understanding of the ultimate objective in the PET value chain. While recyclability was once the key aim, the focus has shifted towards making it possible for materials launched on the market to be collected, sorted, reprocessed, and returned to the market as recyclate multiple times.

-

EPBP Recyclability Evaluation protocol - website version

EPBP Recyclability Evaluation protocol - website version

Update October 2022: The EPBP released an updated version of the Recyclability Evaluation Protocol, incorporating the latest advances in recycling technologies and addressing emerging challenges in the recycling stream.

Member Login

Member Login

News

News