Design Guidelines for PET bottles in contact with food and non-food bottles

The objective of the Design for Recycling Guidelines for PET bottles is to encourage packaging designers, converters and users to integrate certain criteria during the development phase of a new product in order to facilitate PET recycling. The decisions that are made early in the design process can ultimately affect the potential to recycle PET bottles back into high-end applications such as bottles. Then again, the ease with which you can separate and recycle PET bottles can be compromised by many factors including the choice of bottle colour, barrier systems, use of additives, closures composition and labels.

The Design for Recycling Guidelines for PET bottles are based on the requirements for mechanical recycling of post-consumer PET bottles into applications such as bottles, film, sheet, strapping and fibres. Mechanical recycling is the re-melting and transformation of waste materials into new recycled products without changing the basic chemical structure of the processed material.

The key principles of the Design for Recycling Guidelines are appropriate for all PET bottles. These include:

- Avoid the use of materials and/or components that are known to impede the PET recycling process or reduce the quality of the recycled PET.

- Reduce the amount of non-PET components to allow for ease of separation and efficiency of recycling.

- Design components, such as closures and labels, so that they can easily, safely, cost-effectively and rapidly be separated and eliminated from the recycled PET.

- The goal of improving the recyclability of PET bottles cannot compromise product safety.

EPBP strongly encourages the use of the EPBP Design for Recycling guidelines, also for PET bottles that are in contact with non-food products, such as home and personal care products, to further improve the ability to recycle PET bottles in closed loop.

Moreover, EPBP acknowledges that food grade recycled PET, manufactured with the current suitable recycling technologies, according to regulation (EU) 2022/1616 can accept as feedstock only PET food containers that are in compliance with Regulation (EU) No 10/2011 and that originate from municipal waste, or from food retail or other food businesses and which were only intended and used for contact with food, with a maximum threshold of 5% for PET containers that have been in contact with non-food products.

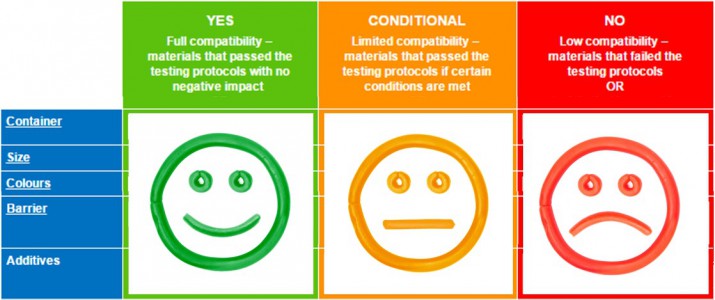

This webpage provides guidance on numerous elements of PET bottle design that have the ability to impede the PET recycling process or reduce the quality of the recycled PET. The summary table provides a snapshot on how to prevent contamination of the PET bottle stream. It also provides specific details that we are unable to convey in the summary table, which can be found by clicking on the hyperlinks (ie. underlined text).

Classification

Materials and/or components used in PET bottles are classified under one of the following categories:

- Full compatibility – Materials that according to the EPBP testing protocol demonstrate no negative impact on the current European PET recycling process (also known as category “YES”). The use of these materials and/or components are encouraged to ensure that PET bottles are highly recyclable. This category also contains some materials and/or components in PET bottles which have not been tested (yet), but are known to be acceptable in PET recycling.

- Limited compatibility – Materials that according to the EPBP testing protocol demonstrate limited impact on the current European PET recycling process (also known as category “CONDITIONAL”). When a use is conditional, it has the ability to negatively impact the PET recycling stream, but these effects are not detrimental if certain conditions are met. For instance, the use of a material and/or component can be limited to a certain weight percent of a particular bottle design in relation to the total PET market. The specific conditions of these materials can be found on our website. This category also contains some materials and/or components in PET bottles which have not been tested (yet), but which our experts believe pose a low risk of interfering with the PET recycling processes or contaminating the recycled PET.

- Low compatibility – Materials that according to the EPBP testing protocol demonstrate a negative impact on the current European PET recycling process (also known as category “NO”). The use of these materials and/or components needs to be restricted because of their detrimental effect on the quality of recycled PET or interference with current PET recycling processes. This category also contains some materials and/or components in PET bottles which have not been tested (yet), but which our experts believe pose a high risk of interfering with the PET recycling processes or contaminating the recycled PET.

Products

Materials and/or components that failed the testing protocol purely as a result of a negative impact on the visual aspects of recycled PET (ie. colour and haze) may be classified in a different category in the clear / light blue PET stream and the coloured PET stream. Our panel of experts has therefore established a set of design for recycling guidelines, for the different types of PET bottles in teh value chain. You can find these design for recycling guidelines in the link below.

It is important to note that the production of food contact grade rPET has the potential to a provide a high value market, but it requires a clear or light blue PET bottle stream due to the problems associated with achieving a consistent colour in the end use application such as bottles or sheet. Markets for coloured rPET are often limited to coloured end-use applications such as strapping or fibers. As a result, colourless / light blue post-consumer PET attracts higher sales prices compared to the darker coloured PET streams.

Click here to view the product data.

Member Login

Member Login

News

News

_1713772260.png)